How can I choose the right product?

Please consider the following aspects:

Please consider the following aspects:

1 • Know our capabilities

Bouveur produces the spiral blades of different lengths and diameters. Lengths can vary from 100mm for small sample machines to 6,500 mm for the largest carpet machines on the global market.

Diameters range from 30 mm to 500 mm for the largest cylinders on the global market.

Each of our spiral blades possesses a reference number. This number identifies each blade and is used to trace the time and the manufacturing conditions. It also enables us to manufacture one or more replacement blades with identical specifications of those former orders.

2 • Understand the caracteristics of spiral blades

We create a wide range of blades based on customer demands and the characteristics required by machine manufacturers. Length, diameter, thickness, number of file cuts, right and left-handed, pitch length. We offer a wide range of file cuts per centimetre and the selection will generally depend on the material for cutting.

Number of file cuts per centimeter offered: 8 – 9 – 10 – 11 – 12 – 13 – 14 – 15 – 16 – 18 – 20 – 22

The pitch length depends on the materials to be sheared and it must be absolutely constant and identical for all blades on the cylinder when replacement.

The role of file cuts

The shearing function is achieved by the combined action of the spiral blades and the ledger blade (counter-blade), in a similar way to how scissors work. The fibres to be cut will tend to slip due to the oblique shearing angle of spiral blades. The role of the file cuts is to prevent slipping while shearing the fabrics. The file cuts work correctly only if they are regular, at the proper angle and of the right depth.

| THICKNESSES, HEIGHTS, LENGTHS AND NUMBER OF FILE CUTS | |||

|---|---|---|---|

| Thickness of spiral blade | 1,5mm | 2mm | 2mm |

| Height of spiral blade | 20mm | 20mm | 23mm |

| Thickness of fabrics | Light to medium | Medium | Thick |

| Number of file cuts / cm | 13 / 14 / 15 / 16 / 18 | 12 / 13 / 14 | 8 / 9 / 10 / 11 / 12 / 13 |

| Length of the spiral blade | 100mm to 6500mm | 100mm to 6500mm | 100mm to 6500mm |

3 • Choose your fabrics and machine manufacturers

| FABRICS FOR SHEARING | NUMBER OF FILE CUTS / CM | THICKNESS AND HEIGHT OF BLADE |

|---|---|---|

| Worsted yarn / carded yarn | 18 | 1,5mm – H 20mm |

| Weave cotton fabric | 13 / 14 / 0 | 1,5mm – H 20mm |

| Woolen cloth | 13 / 14 | 1,5mm – H 20mm |

| Embroidery | 15 / 16 / 18 / 0 | 1,5mm to 2mm – H 20mm |

| Velours | 13 / 14 | 1,5mm to 2mm – H 20mm |

| Highly resistant technical fabrics | 13 / 14 / 15 / 16 | 2mm – H 20mm |

| Polar | 15 / 16 | 1.5mm – H 20mm |

| Circular knit fleecee | 13 / 14 / 15 / 16 | 1.5mm – H 20mm |

| Duffel | 13 / 14 / 15 / 16 / 18 | 1.5mm to 2mm – H 20mm |

| Carpet | 8 / 9 / 10 / 11 / 12 | 2mm – H 23mm |

| Sisal / Coconut fiber | 8 / 9 / 10 / 11 / 12 | 2mm – H 23mm |

Bouveur spiral blades fit all kinds of machine manufacturers

Anhui Laifu

Anmak

Bailey

Bailey James

Bejimac

Bitexma

Broma

Capdevilla

Caru

Changzhou KunLiang

Changzhou Machinery Works

Changzhou ShengWang

Changzhou TongYue Machinery

Chien Lun

Clasen

Cogliati

Comet

Curtis & Marble

Crane Valve

Crosta

Danti Paolo

Diriler

EFAB

Feraro Cometex

Fontanet

Gematex

Gessner

Grosselin

Grosselin Bouveur

Guido Regis

GSL

Haining FangJi Machinery Works

Hämmerle

Hergert

Holthausen

Huang

Ikuang Machine Works

Iwakura

JiangSu

Jinan Sinotech

Kettling & Braun

Lafer

Lafer Turk

Lamperti

Lamperti Antonio

Lian Yun Gang

Lidem

Mario Crosta

Menschner

Miliken

Monfort

Mortamet

M-tec

MTW

Muller Franz

Munsinger

Nikki

Parks & Woolson

PengLeng

Peyman Machine Isfahan

Raxhon

Riley

Saber

Sai Sukritii International

Santa Clara

Sara Tex

Scholaert

Sellers

Shaterian

Shanghai Good Grinding

Sistig

Sucker/Müller

Surber

Tacome

TianJin HuaDi LianXin

TMT

Torres

Unitech

WuXi Xin Yi

Xetma Vollenweider

4 • Inquire about the fixing

5 • Our techniques

The importance of cutting blades

No matter how developed the modern textile shearing machines are in the design and manufacture, the blades always play an essential role. Their quality represents the core of a shearing machine and determines the final shearing effect of the fabrics.

Our priorities

1) Cutting efficiency

2) Cutting quality

3) Life span

The Bouveur Spiral Blade

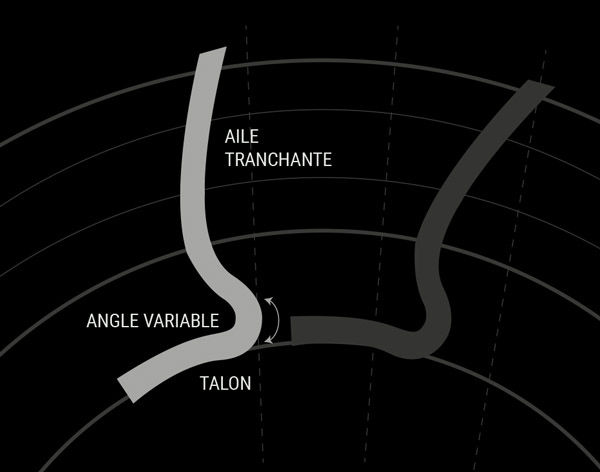

The spiral blade, from the sectional view, is composed by two parts

- The cutting wing, normally file cut (with teeth).

- The heel which is attached onto the body of the cylinder gives the maximum strength to the blade and enables it to cut the material in the best conditions of efficiency and duration.

- The cutting wing needs to be curved and it should remain constant until the blade has completely worn out.

- The role of the heel is essential as it ensures the stability of the blade on the cylinder.

- If we want to obtain the consistent cutting angel, the shape formed at the heel needs to be changed based on the diameter of the cylinder and the length of the pitch. This is the basic rule which can never be ignored. It also requires that the degree of twist and the winding diameter of blades should be calculated in such way so that the concave inner face of the heel can be attached onto the cylinder well tightly over its whole length. It means that each type of the spiral blade requires a special manufacturing process corresponding to its characteristics.